Maple

Vermont’s Sweetest Export

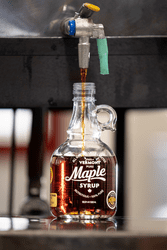

Vermont Maple Products

When cold nights and warm spring days trigger the flow of sap in Vermont’s sugarbushes, they experience their very own gold rush. Vermont makes more than half the country’s maple syrup, more than any other state. In 2024, Vermont’s sugar makers produced a record of 3.1 million gallons. All that maple is processed in more than 3,000 sugarhouses statewide, from smaller family-run operations to industrial syrup producers, and ends up as part of cocktail infusions, dry rubs, hot sauces, candy, and on shelves as syrup and sugar.

Find a Vermont Sugar Maker

From touring a sugarhouse in the spring as sap boils down to grabbing a maple creemee by the side of the road, Vermont maple is an immersive experience.

Find a Sugar MakerApril’s Maple

Visit 800 acres of sugaring forest in Canaan, tour the reverse osmosis syrup production facility, and sample syrup grades as well as sauces, rubs, and creemees.

Read More about April’s MapleRead MoreMorse Farm Maple Sugarworks

Visit this Montpelier sugarhouse, open to the public, to learn how pure Vermont maple is made, sample different grades, and enjoy a maple creemee.

Read More about Morse Farm Maple SugarworksRead MoreSilloway Maple

A family business since 1940, Silloway Maple welcomes visitors for tours, tastings, and retail. The facility uses cutting-edge technology, in tandem with a wood fire, in their sugaring operation.

Read More about Silloway MapleRead MoreBaird Farm

For more than 100 years, Baird Farm has produced pure Vermont maple on 560 acres in North Chittenden. Visit year-round to learn about the process and sample the goods.

Read More about Baird FarmRead MoreMerck Forest and Farmland

This Rupert farm is free and open to the public every day year-round. Their sugarbush contains 2,900 taps.

Read More about Merck Forest and FarmlandRead MoreBourdon Maple

This generational Woodstock farm uses up to 10,000 taps each season, making them a sugaring powerhouse.

Read More about Bourdon MapleRead MorePalmer Lane Maple

This local-loved Jericho spot sells creemees and pure Vermont maple syrup, cream, sugar, candy, and more.

Read More about Palmer Lane MapleRead MoreSlopeside Syrup

Located near Cochran’s Ski Area, these individual packets of pure Vermont maple offer a quick, healthy energy source, whether you’re shredding on skis or a bike or just need a boost.

Read More about Slopeside SyrupRead MoreRunamok Maple

This sweet spot makes honey and cocktail mixers as well as its signature sparkly maple syrup with edible glitter.

Read More about Runamok MapleRead More

Vermont Maple Open House Weekend

March 22-23, 2025

For two weekends in late winter and early spring, sugar makers around the state open their doors and invite the public in for tours and samples. Follow the sweet steam around the Green Mountains.

The sugar-making process has evolved from sap buckets carried through the woods on a horse-drawn sleigh to today’s ultra-modern reverse osmosis technology. Vermont’s sugar makers use a diverse mix in their operations.

Maple is a Natural Kitchen Powerhouse

Nestled in Woodstock, Vermont, Cloudland Farm chef Mike Boraccio finds cooking to be a form of moving meditation. His philosophy is “What grows together goes together,” which means he can design an entire menu around pure Vermont maple.

Butternut Mountain Farm’s maple syrup made it onto the International Space Station in squeeze bottles as part of astronauts’ rations.

Vermont Maple Sugar Makers Association

Vermont Maple Sugar Makers Association is the online home of Vermont’s maple industry. Buy syrup online, learn more about what the different grades mean, and find recipes, including a guide to substituting maple sugar for granulated white.

Learn More about Vermont Maple Sugar Makers Association